object(stdClass)#217 (18) {

["Sort"] => string(1) "4"

["ModId"] => string(2) "46"

["ModName"] => string(4) "SM5C"

["CatId"] => string(2) "33"

["ModOverview"] => string(74) "- Vessel interchange type

- Volume:1ℓ, 3ℓ, 5ℓ

- Easy to operate

"

["ModListImage"] => string(4) "1398"

["ModMainImage"] => string(4) "1399"

["ModVideo"] => string(1) "0"

["ModContent"] => string(500) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174252012335867.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(125) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825619228730.png" alt="" width="1080" height="729" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1466580223"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(1) "1"

}

object(stdClass)#217 (18) {

["Sort"] => string(1) "4"

["ModId"] => string(2) "46"

["ModName"] => string(4) "SM5C"

["CatId"] => string(2) "33"

["ModOverview"] => string(74) "- Vessel interchange type

- Volume:1ℓ, 3ℓ, 5ℓ

- Easy to operate

"

["ModListImage"] => string(4) "1398"

["ModMainImage"] => string(4) "1399"

["ModVideo"] => string(1) "0"

["ModContent"] => string(500) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174252012335867.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(125) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825619228730.png" alt="" width="1080" height="729" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1466580223"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(1) "1"

}

SM5C

object(stdClass)#192 (18) {

["Sort"] => string(1) "4"

["ModId"] => string(2) "48"

["ModName"] => string(3) "D5L"

["CatId"] => string(2) "34"

["ModOverview"] => string(164) "- Volume: 1ℓ ~ 5ℓ

- Filter change type

- Upward and downward spray system

- Heat exchanger and dust collector built-in type (ejector type)

- 21 CFR Part 11"

["ModListImage"] => string(4) "1495"

["ModMainImage"] => string(4) "1449"

["ModVideo"] => string(1) "0"

["ModContent"] => string(500) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174252022818785.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825623369339.png" alt="" width="1080" height="1557" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1466580223"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(1) "4"

}

object(stdClass)#192 (18) {

["Sort"] => string(1) "4"

["ModId"] => string(2) "48"

["ModName"] => string(3) "D5L"

["CatId"] => string(2) "34"

["ModOverview"] => string(164) "- Volume: 1ℓ ~ 5ℓ

- Filter change type

- Upward and downward spray system

- Heat exchanger and dust collector built-in type (ejector type)

- 21 CFR Part 11"

["ModListImage"] => string(4) "1495"

["ModMainImage"] => string(4) "1449"

["ModVideo"] => string(1) "0"

["ModContent"] => string(500) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174252022818785.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825623369339.png" alt="" width="1080" height="1557" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1466580223"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(1) "4"

}

D5L

object(stdClass)#191 (18) {

["Sort"] => string(1) "3"

["ModId"] => string(2) "49"

["ModName"] => string(4) "D5LM"

["CatId"] => string(2) "34"

["ModOverview"] => string(103) "- D5L function available

- Economic processing

- Volume: 1ℓ, 3ℓ, 5ℓ (Mixer)

- 21 CFR Part 11

"

["ModListImage"] => string(4) "1494"

["ModMainImage"] => string(4) "1451"

["ModVideo"] => string(3) "478"

["ModContent"] => string(500) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174252026484428.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825625134959.png" alt="" width="1080" height="1643" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1466580223"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(1) "5"

}

object(stdClass)#191 (18) {

["Sort"] => string(1) "3"

["ModId"] => string(2) "49"

["ModName"] => string(4) "D5LM"

["CatId"] => string(2) "34"

["ModOverview"] => string(103) "- D5L function available

- Economic processing

- Volume: 1ℓ, 3ℓ, 5ℓ (Mixer)

- 21 CFR Part 11

"

["ModListImage"] => string(4) "1494"

["ModMainImage"] => string(4) "1451"

["ModVideo"] => string(3) "478"

["ModContent"] => string(500) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174252026484428.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825625134959.png" alt="" width="1080" height="1643" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1466580223"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(1) "5"

}

D5LM

object(stdClass)#225 (18) {

["Sort"] => string(2) "10"

["ModId"] => string(2) "30"

["ModName"] => string(5) "P130S"

["CatId"] => string(2) "29"

["ModOverview"] => string(145) "- Plug and play

- 21 CFR Part 11

- For R&D and clinical test use

- Automatic weight control function

- Mechanical Feeder (bar and round type)"

["ModListImage"] => string(4) "1498"

["ModMainImage"] => string(4) "1499"

["ModVideo"] => string(3) "104"

["ModContent"] => string(1285) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174251860207066.png" alt="" width="700" /></p>

<p style="text-align: left;"> </p>

<p style="text-align: left;"> Production capacity is based on the tablet porosity at 0.3 at density 0f 0.7 and the resule may vary depending on tablet and pan speed.</p>

<p style="text-align: left;"> Coating volume is calculated based on the maximum production capacity. Use safety ratio of safe operation.</p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825630931268.png" alt="" width="1080" height="2299" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1466580223"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(1) "8"

}

object(stdClass)#225 (18) {

["Sort"] => string(2) "10"

["ModId"] => string(2) "30"

["ModName"] => string(5) "P130S"

["CatId"] => string(2) "29"

["ModOverview"] => string(145) "- Plug and play

- 21 CFR Part 11

- For R&D and clinical test use

- Automatic weight control function

- Mechanical Feeder (bar and round type)"

["ModListImage"] => string(4) "1498"

["ModMainImage"] => string(4) "1499"

["ModVideo"] => string(3) "104"

["ModContent"] => string(1285) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174251860207066.png" alt="" width="700" /></p>

<p style="text-align: left;"> </p>

<p style="text-align: left;"> Production capacity is based on the tablet porosity at 0.3 at density 0f 0.7 and the resule may vary depending on tablet and pan speed.</p>

<p style="text-align: left;"> Coating volume is calculated based on the maximum production capacity. Use safety ratio of safe operation.</p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825630931268.png" alt="" width="1080" height="2299" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1466580223"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(1) "8"

}

P130S

object(stdClass)#226 (18) {

["Sort"] => string(1) "8"

["ModId"] => string(2) "58"

["ModName"] => string(5) "P230D"

["CatId"] => string(2) "29"

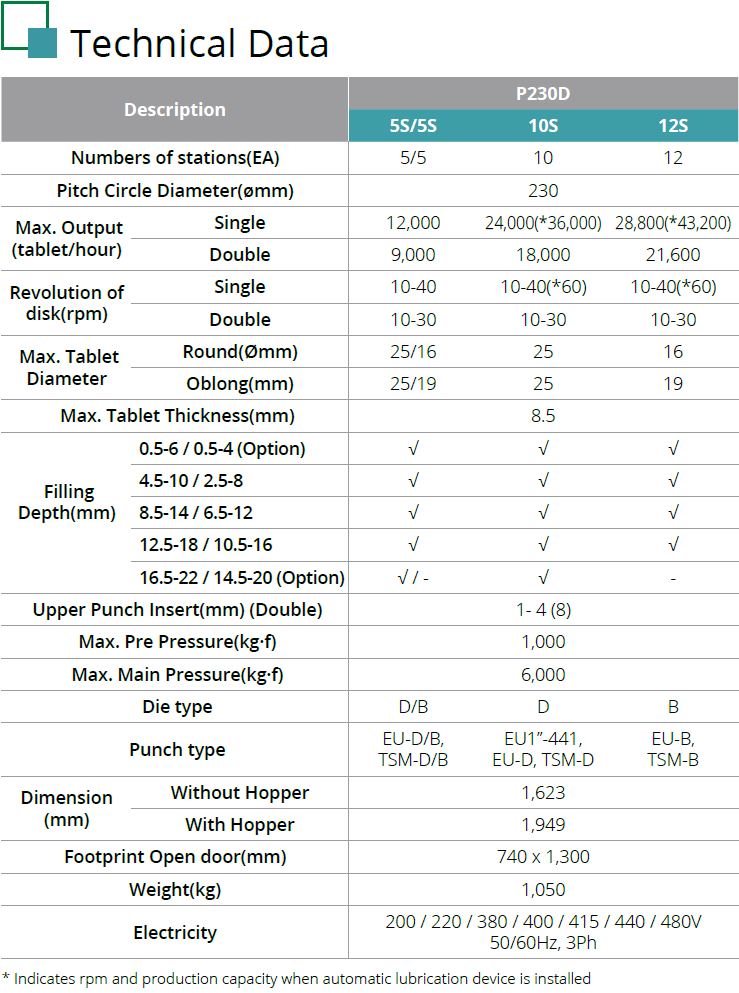

["ModOverview"] => string(150) "•Compact and lightweight design

•Wide usage with single and bi-layer tablet compression

•Auto-sampling First-layer during Bi-layer production"

["ModListImage"] => string(4) "1500"

["ModMainImage"] => string(4) "1501"

["ModVideo"] => string(3) "471"

["ModContent"] => string(1256) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174251822570520.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> </p>

<p style="text-align: left;"> Pre Pressure and main pressure could be vary depending on tablet size, filling depth and feature or granuls.</p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>

<p style="text-align: left;"> rpm could be vary based on filling depth and powder features.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825629317115.png" alt="" width="1080" height="2477" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1597801661"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(2) "57"

}

object(stdClass)#226 (18) {

["Sort"] => string(1) "8"

["ModId"] => string(2) "58"

["ModName"] => string(5) "P230D"

["CatId"] => string(2) "29"

["ModOverview"] => string(150) "•Compact and lightweight design

•Wide usage with single and bi-layer tablet compression

•Auto-sampling First-layer during Bi-layer production"

["ModListImage"] => string(4) "1500"

["ModMainImage"] => string(4) "1501"

["ModVideo"] => string(3) "471"

["ModContent"] => string(1256) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174251822570520.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> </p>

<p style="text-align: left;"> Pre Pressure and main pressure could be vary depending on tablet size, filling depth and feature or granuls.</p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>

<p style="text-align: left;"> rpm could be vary based on filling depth and powder features.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825629317115.png" alt="" width="1080" height="2477" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1597801661"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(2) "57"

}

P230D

object(stdClass)#227 (18) {

["Sort"] => string(1) "5"

["ModId"] => string(2) "43"

["ModName"] => string(3) "C30"

["CatId"] => string(2) "32"

["ModOverview"] => string(144) "- Heat exchanger and dust collector built-in type

- Supply and discharge system

- Dual cover type for preventing heat loss

- 21 CFR Part 11

"

["ModListImage"] => string(4) "1518"

["ModMainImage"] => string(4) "1519"

["ModVideo"] => string(3) "489"

["ModContent"] => string(1287) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174251739271462.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> Production capacity is based on the tablet porosity at 0.3 at density 0f 0.7 and the resule may vary depending on tablet and pan speed.</p>

<p style="text-align: left;"> Coating volume is calculated based on the maximum production capacity. Use safety ratio of safe operation.</p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825659531472.png" alt="" width="1080" height="1845" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1466580223"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(2) "22"

}

object(stdClass)#227 (18) {

["Sort"] => string(1) "5"

["ModId"] => string(2) "43"

["ModName"] => string(3) "C30"

["CatId"] => string(2) "32"

["ModOverview"] => string(144) "- Heat exchanger and dust collector built-in type

- Supply and discharge system

- Dual cover type for preventing heat loss

- 21 CFR Part 11

"

["ModListImage"] => string(4) "1518"

["ModMainImage"] => string(4) "1519"

["ModVideo"] => string(3) "489"

["ModContent"] => string(1287) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174251739271462.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> Production capacity is based on the tablet porosity at 0.3 at density 0f 0.7 and the resule may vary depending on tablet and pan speed.</p>

<p style="text-align: left;"> Coating volume is calculated based on the maximum production capacity. Use safety ratio of safe operation.</p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825659531472.png" alt="" width="1080" height="1845" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1466580223"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(2) "22"

}

C30

object(stdClass)#228 (18) {

["Sort"] => string(1) "5"

["ModId"] => string(2) "54"

["ModName"] => string(2) "F3"

["CatId"] => string(2) "30"

["ModOverview"] => string(255) "- Preliminary rejection system of unseparated capsules by detect-ing vacuum pressure differential.

- Micro tablet filling quantity control by optical sensor.

- Various quantities of micro tablets to be filled by one disk

- Improved productivity and red"

["ModListImage"] => string(4) "1486"

["ModMainImage"] => string(4) "1487"

["ModVideo"] => string(1) "0"

["ModContent"] => string(886) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174251973829662.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> Productivity and accuracy of the production are vary depending on the physical specification of powder of pellet.</p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825644382190.png" alt="" width="1080" height="1187" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1550716866"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(2) "53"

}

object(stdClass)#228 (18) {

["Sort"] => string(1) "5"

["ModId"] => string(2) "54"

["ModName"] => string(2) "F3"

["CatId"] => string(2) "30"

["ModOverview"] => string(255) "- Preliminary rejection system of unseparated capsules by detect-ing vacuum pressure differential.

- Micro tablet filling quantity control by optical sensor.

- Various quantities of micro tablets to be filled by one disk

- Improved productivity and red"

["ModListImage"] => string(4) "1486"

["ModMainImage"] => string(4) "1487"

["ModVideo"] => string(1) "0"

["ModContent"] => string(886) "<p style="text-align: center;"><img src="/upload/ckeditor/250321/174251973829662.png" alt="" width="700" /></p>

<p style="text-align: center;"> </p>

<p style="text-align: left;"> Productivity and accuracy of the production are vary depending on the physical specification of powder of pellet.</p>

<p style="text-align: left;"> Specifications and dimensions are subject to change without prior notice.</p>"

["ModContentMobile"] => string(126) "<p style="text-align: center;"><img src="/upload/ckeditor/211130/163825644382190.png" alt="" width="1080" height="1187" /></p>"

["ViewCount"] => string(1) "0"

["RegDate"] => string(10) "1550716866"

["UserId"] => string(2) "14"

["ifNew"] => string(1) "N"

["ifModNameView"] => string(1) "Y"

["ifMain"] => string(1) "N"

["ifOptional"] => string(1) "N"

["SourceModId"] => string(2) "53"

}

F3